Group Facilities

The JPL Electrochemical Research, Technology, & Engineering Group maintains extensive, end-to-end capabilities for developing new battery, supercapacitor and fuel cell materials and components, incorporating them into prototype cells, and testing them over a wide range of conditions. In addition to cell and battery level testing, our group maintains a full range of analytical capabilities for conducting fundamental electrochemical measurements, including potentiostats/galvanostats, rotating disk electrodes and frequency response analyzers.

Modeling

- COMSOL: Multi-physics modeling tool for thermal, mechanical, electrical, and magnetic processes

- Gaussian: Computational chemistry tool for performing molecular mechanics and quantum mechanical calculations

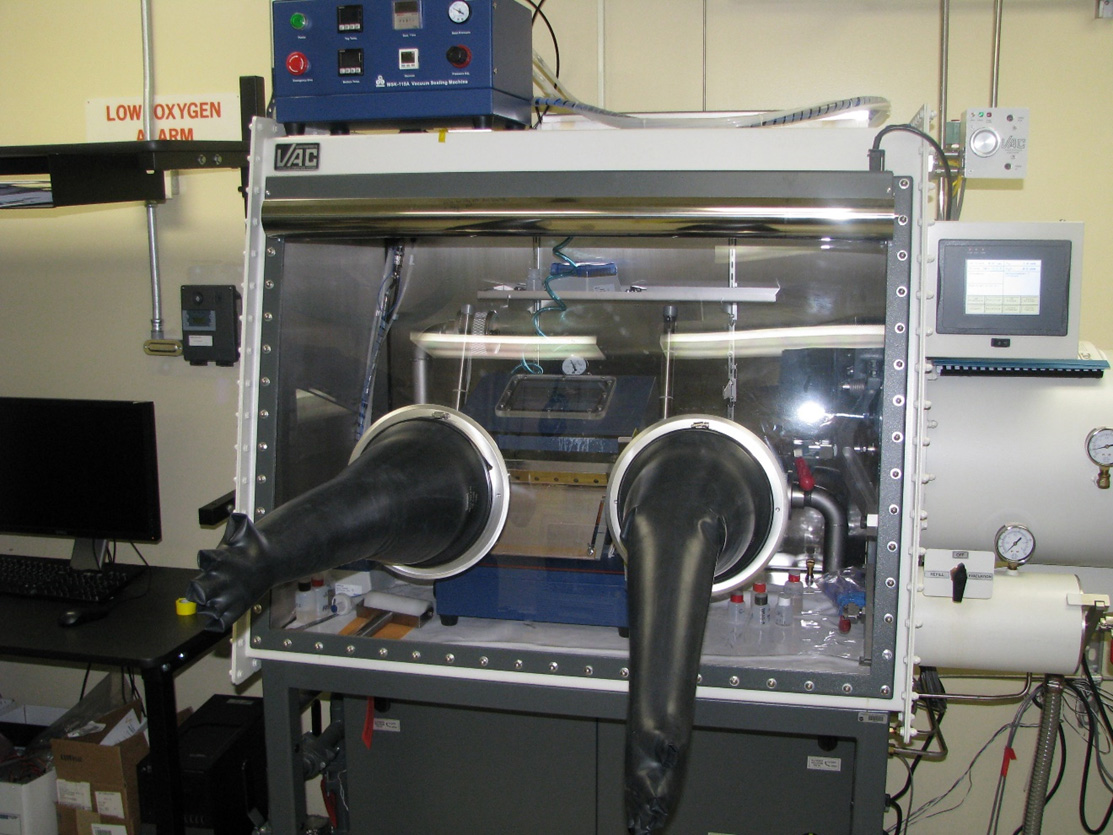

Advanced materials synthesis and characterization

- Inert atmosphere gloveboxes

- Dry room

- Differential scanning calorimeter

- Tap density measurements

- Karl Fischer titration

Cell assembly

Our group employs a variety of prototype cell formats which can be assembled in house, including coin cells, glass cells and pouch cells. In addition, we work closely with various vendors to incorporate the latest advanced materials into wound and prismatic cells, for high fidelity, long life testing.

JPL maintains a variety of equipment for taking advanced materials and turning them into electrodes and incorporating them into cells:

- Deposition and calendaring

- Vacuum drying ovens

- Presses

- Spot welders

- Coin cell and pouch cell fabrication equipment

Cell and battery testing

Our group has a comprehensive suite of battery test units and chambers for safely evaluating batteries for the rigors of space or terrestrial applications. These chambers are used for testing flight hardware, as well as evaluating advanced cells in support of our technology development programs. These capabilities include:

- 21 thermal test chambers, for evaluation of test cells from -80°C to +200°C

- 6 Maccor units for testing

- Hydrogen fuel cell and electrolyzer test stands