Research - Electrodeposition and Thin Film Techniques

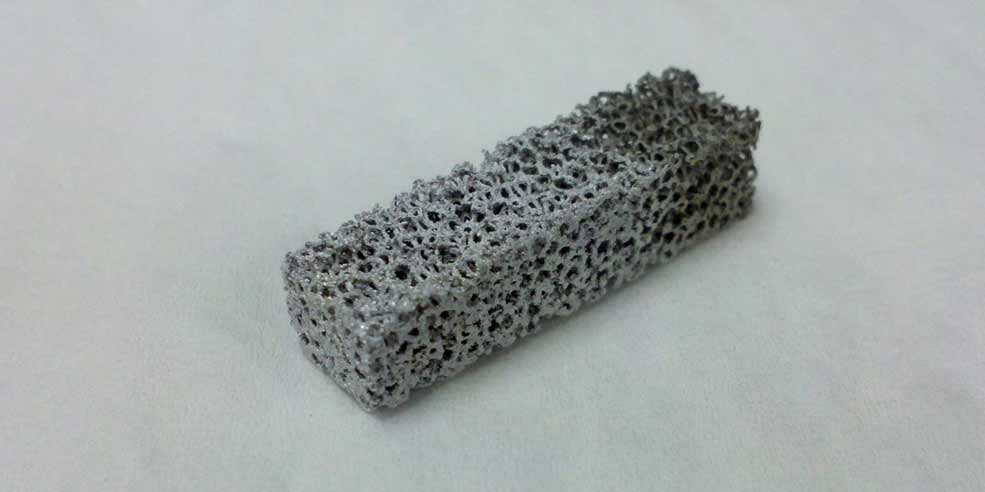

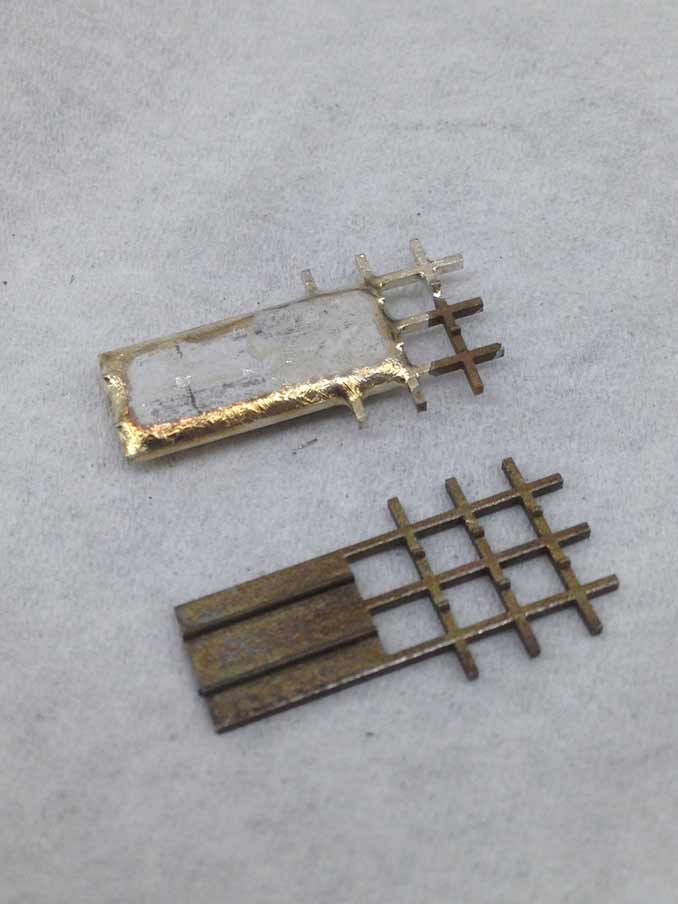

The deposition of materials using electrochemical means (electroplating, or electrodeposition) plays an increasingly important role in numerous technology areas. Various JPL technology development efforts require electroplating, due to the need for the deposition of novel, thick film materials, or due to the use of a complex, underlying shape that does not lend itself to traditional physical deposition techniques.

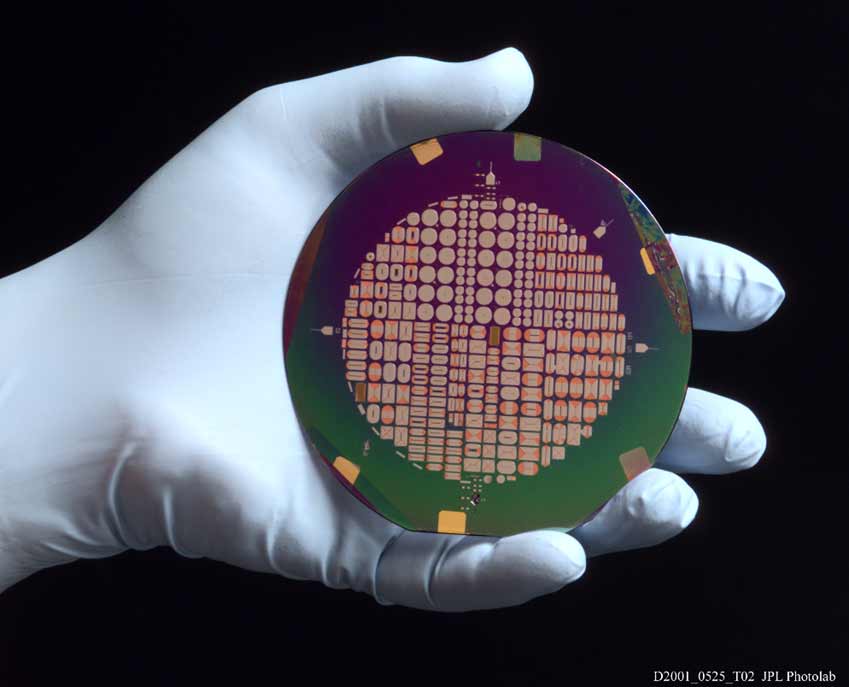

The JPL Electrochemical Research, Technology, & Engineering Group is often called upon to utilize its expertise in electrodeposition, to support these development efforts. Previous efforts include the development of advanced micro-thrusters, as well as miniaturized power magnetic devices such as inductors and transformers, for highly integrated power electronics. Finally, advanced sputtering techniques are used to deposit solid state electrolytes, for the fabrication of highly miniaturized, planar battery cells.